QUALITY MADE IN ITALY CMS BREMBANA milestone s is an advanced, versatile, high-performance waterjet cutting system, either pure water or hydro-abrasive, able to accommodate the most diverse production demands in differen....

A BIGGER CUTTING TABLE FOR LARGER PROJECTS - WOOD, MOSAIC, TILE, GLASS, COMPOSITE, STONE, METAL ,STEEL, FIBRE AND MORE. We recommend gantry type waterjet systems for the customers who need a bigger cutting table. SYSTEMS ARE SIMPLE AND EASY TO USE. Can be custom made to your needs. Gantry type is very firm waterjet structure. The bridge hanging the cutting head sits on two base beams which are completely separated from the working table. Machine structure Common sizes 2000mm x 4000mm, 2000mm x 6000mm 2500mm x 4000mm, 3000mm x 6000mm We also can customize the machine size upon custome....

The Flow Mach 100 waterjet previously Mach 2B is an industrial waterjet machine for operations looking to integrate the versatility of waterjet cutting into their process at a cost-effective price. Whether your application is to cut aluminium, stainless or mild steel, rubber, composites, plastics or cement sheet, the Mach 100 is a reliable workhorse designed to withstand the rigors of your day-to-day production, enabling workpiece loads of up to 400kg per square meter of table area. Linear accuracy - 0.13mm m Repeatability - 0.064mm Not available with 5 axis cutting technology High P....

QUALITY MADE IN ITALY The Cms Brembana EASYLINE 5-Axis Waterjet Machine represents high quality engineering coupled with extra functionality to ensure that production is efficient and low cost as well as accurate. The highlights of the EASYLINE 2040S Waterjet Machine are multiple. Access from 3 sides of the machine gives the operator more control and a higher level of safety. The designers have anticipated things such as automatic changing of the parameters when thicker or different materials need to be cut at different speeds. The unique GreenJET ELECTRICAL INTENSIFIER PUMP, designe....

World s Fastest Waterjet. Flow s Mach 500 is a top-of-the-line waterjet system that is unrivalled in features, accuracy and cutting speed. With 87,000psi Mach 500 s astounding cut speed drives overall part processing tim....

WAZER WAZER STANDUP CNC Waterjet The world first Desktop Waterjet - CUT ANYTHING ON DEMAND International version b BONUS BUNDLE b CALL NOW AND DO A DEAL ADD THIS ASSET TO YOUR WORKSHOP WE OFFER MACHINERY SOLUTIONS AT AFF....

AM Water Jet provide a common FLOW type cutting head and ACCU type high efficiency cutting head imported from USA . The ACCU cutting head can improve the cutting speed by more than 20 . AM Waterjet TRUMP50 series water c....

QUALITY MADE IN ITALY CMS BREMBANA PROLINE - The ultimate machine tool specifically conceived and designed with advanced technical solutions for the waterjet cutting technology, in order to achieve unmatched performance.....

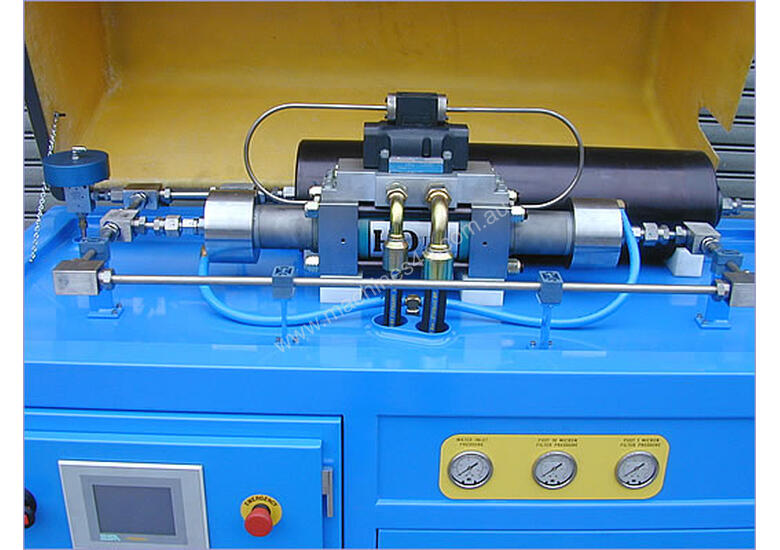

The cutting table consists of a transmission part with X-axis, Y-axis and Z-axis, water tank, cutting head, lubrication part and servo driving system. Cantilever mechanical structure is fit to small size machines, a short running distance of X and Y axis, simple structure, suitable for processing a variety of complex small parts. Product information SAME cantilever type waterjet cutting machine is available in many sizes 1600mm x 1600mm, 2500mm x 1600mm, 3000mm x 2000mm, 4000mm x 2000mm, etc. Customized service is available. The price quoted is for a 4000mm 2000mm actual cutting rang....

AccurlCMT water jet cutting machines are part of the stable of high quality machines offered by AccurlCMT that form part of the cutting, bending and forming portfolio. Multiple table sizes are available starting with1200....

WAZER WAZER DESKTOP CNC Waterjet The world first Desktop Waterjet - CUT ANYTHING ON DEMAND International version b BONUS BUNDLE b CALL NOW AND DO A DEAL ADD THIS ASSET TO YOUR WORKSHOP WE OFFER MACHINERY SOLUTIONS AT AFF....

The Tecnocut Waterspeedy S is a waterjet system designed specifically for the high-speed processing of plastics capable of providing an exceptional materials, layered materials, industrial seals and technical material. T....

Like new Prussiani 5 axis waterjet with only 1400 hrs on the KMT pump. The NEW RIO 5 machine, distinguished by its mobile bridge structure, has been specifically designed and built to carry out water or abrasive jet cutt....

The AitalMAC CNC SawJet Orbit A5 combination machine has everything a technologically advanced Water Jet and Bridge Saw needs for the modern-day stonemason a 5 interpolated Axis Spindle with half inch fitting and Through....

QUALITY MADE IN ITALY The CMS TECNOCUT Smartline is designed to redefine industry standards of excellence by improving operating efficiency, while maintaining CMS renowned reputation for unparalleled construction and wor....

The gantry-type cutting table consists of the transmission part with the X-axis, Y-axis and Z-axis, water tank, cutting head, lubrication part and servo driving system. Gantry mechanical structure is fit to large size machines, a long-running distance of X and Y axis, suitable for processing a variety of complex big size parts. Features The gantry type cutting table consists of transmission part with X axis, Y axis and Z axis, water tank, cutting head, lubrication part and servo driving system. Gantry mechanical structure is fit to large size machines, long-running distance of X and ....

Omax 1530 maxiem Gen 2 40 hp direct drive omax pump Full pump rebuild just done Rapid water level control 250kg abrasive feed hopper Water conditioner kit Hours 1867 The machine was used in a small workshop for it own manufacturing hances the low hrs. ....

The cutting table is equipped with dual-head or multi-head structure. With the professional cutting software, it can perform the same track cutting task at the same time. Features The cutting table is equipped with dual-head or multi-head structure. With the professional cutting software, it can perform the same track cutting task at the same time. Mainly suitable for large quantities of mosaic, foot line and other large variety of products processing and cutting. The advantages of using it in production, efficiency, cost control and other aspects makes it effective. Product informat....