- October 17, 2017

- No Comment

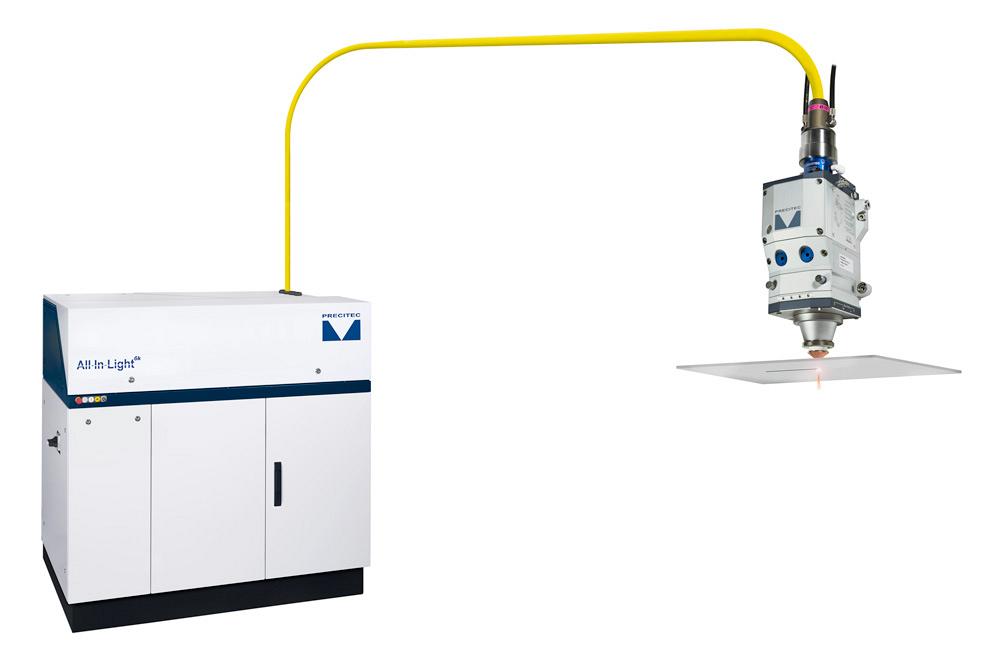

From the beam source to the cutting head – The New complete ‘All-In-Light’ package from Precitec

Precitec’s new ‘All-In-Light’ package offers an attractive solution for the complete optical chain from the laser, and the laser light fibre to the cutting head. This package is made possible by a strategic cooperation with the laser specialist Trumpf. It makes the disc laser technology available for manufacturers of flatbed and tube cutting machines.

Combined core competences

Manufacturers of laser cutting machines can now benefit from the new long-term strategic cooperation between Trumpf and Precitec. This cooperation offers the complete optical chain for laser cutting from a single source, and more specifically to advance new developments in order to provide a perfectly coordinated, optimal package including sophisticated features. Plus, the benefit from the combination of state-of-the-art laser technology and innovative cutting head technology and the additional benefits provided by a ‘One-Stop-Shop’ giving a reduction in complexity and easier sourcing and purchasing of parts.

Precitec will continue to maintain its independence and cooperate closely with all laser source manufacturers. Therefore, the company can optimally respond to its customer wishes and offer tailored solutions.For several years now, disc laser technology has been proving its extraordinary worth in industrial laser cutting and welding. This technology is characterised by highest performance stability, easy servicing and low costs.

Precitec offers the ‘All-In-Light’ cutting package internationally with a power of 1 to 6kW. 8kW are currently being tested and solutions for up to 10kW are already being developed. With targeted product developments in recent months, Precitec has been successful in significantly improving the cutting quality especially nitrogen cutting of stainless steel with thicknesses exceeding 30mm. In this way OEM customers and job shops are given the opportunity to equip their cutting systems more competitively in the field of both thin and thick sheets.

Global service Users are provided with comprehensive service around the clock via the global Precitec network. In-house Precitec service employees in Asia, Europe and North America are intensively trained on disc laser technology and ProCutter, LightCutter and Mini- Cutter cutting heads.

Precitec offers training for services and sales staff on the entire optical chain at its application and distribution centres across the USA, Australia, Europe and Asia, and remote maintenance via remote diagnostics, and stocking of spare parts on-site guarantee shortest response times.

Technical Data