- February 22, 2023

- No Comment

What is Required for Dry Ice Blasting?

Presented by AKA Cleaning

Sounds straight forward, but is it? Let’s start with brief outline of what is required to do dry ice blasting as there is a lot more to it than the actual blaster.

There are 4 major components required:

- The air supply

- The Blast unit

- The dry Ice supply

- The skilled operator

Let’s break these down so we can get a clear understanding of the requirements and hence the costs that are involved.

1. The Air Supply

Dry ice blasting requires a supply of compressed air to project the dry ice pellets onto the surface to be cleaned.

From experience with many customers, AKA Cleaning ask a couple of initial questions to get a sense for their customers ability to provide the required air supply. These conversations usually go as follows:

Q. Do you have a supply of compressed air?

A. Sure

Q. Do you know the volume and pressure of air that you have available?

A. Yep, no problem. We have loads.

Unfortunately, it turns out most don’t actually know just how much air it takes to make a dry ice blaster work at its optimum level. Depending on the blaster and the size (I.D.) of the pipes and blast hose, this can make a huge difference.

Two Factors to Consider: Volume of Air & Pressure of Air

There are two factors that need to be considered: the volume of air and the pressure of air.

The volume dictates how fast the blaster can work—too little air and the flow will not keep up with blaster. Pressure determines the aggression of the clean—the more pressure you have the easier it is to remove the contaminant.

There is a balance between pressure and volume which will affect the efficiency of the blasting system.

Air Supply Options

Air can be supplied from a permanently installed compressor in say a factory or workshop situation. These can be sufficient to run small blasting units and may be suitable for light jobs that don’t require large aggressive blasting. They tend to supply 6-7bar of pressure and usually have just enough volume to keep up with small blasters.

Air can also be supplied from a portable diesel compressor that can be towed to any site. This will generally be required to power larger blasting systems. Compressors that provide 200cfm up to 450cfm and 8-14bar in pressure will generally be required for larger blasting units.

The outlay for a new compressor in the 200cfm -400cfm range can be from $30k-$65K depending on the size. AKA Cleaning find that most customers will hire a compressor for the period they require and cost this into individual jobs—hire rates are around $300-$500/day.

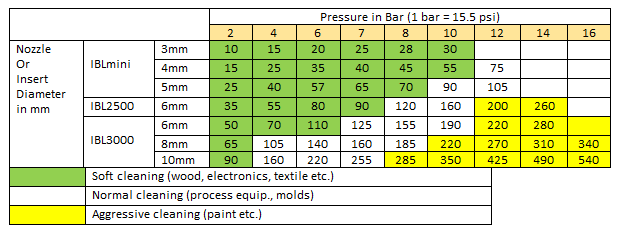

The chart below gives an indication of pressures and volumes required for their “Intelblast” range of dry ice blasters.

Airflow & Pressure Selection Chart

2. The Blaster

These come in many sizes and many variations, as well as huge variations in price. Some have fancy gauges and readouts, while others are more basic and built to do a specific job.

Quality of build is a big consideration. These machines are running large volumes of air and very high pressures and blasting out dry ice pellets which are at -79C.

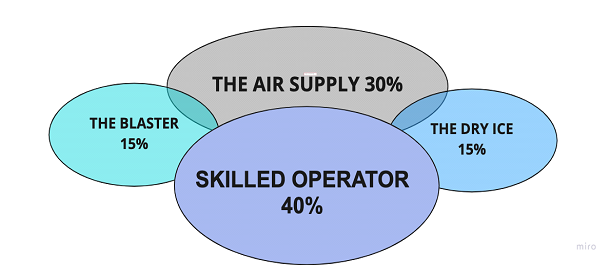

AKA Cleaning believe that the blaster is approx. 15% of the system. Sure, it must be reliable but the other factors: air supply, air quality, quality hard dry ice and the skill of the operator make up the balance.

It’s one thing to have a machine with lots of “Bells & Whistles” but the biggest consideration is performance over time.

Spare parts availability is also another consideration. Let’s face it, all machines will break-down at some time and dry ice blasters are usually working in harsh environments. Availability of replacement parts, ease of service and a knowledgeable service back-up team are big factors.

3. Dry Ice Supply

Without dry ice supply you have nothing. Dry ice is solid Carbon Dioxide (CO2).

For blasting AKA Cleaning generally use 3mm dry ice pellets. The pellets are produced with a dry ice pelletiser which extrudes 3mm diameter straws of solid dry ice through a dye on the pelletising machine. Liquid CO2 is depressurised in a chamber, and this forms a “CO2 snow”. This snow is then compressed at very high pressure and forced out of the dye to form the straws of solid CO2.

Dry ice pellets are most effective when they are fresh. Fresh pellets are hardest and most effective when used within 1-2 days of production, the sooner the better. Dry ice pellets are usually delivered in large, insulated ice boxes which will maintain the pellets quite well for up to 3 days. Because the pellets are produced at -79C they are extremely difficult to maintain for any extended length of time and will slowly sublimate over time and lose approx. 10% of their volume / day depending on how they’re stored.

Keeping the lid closed on the container as much as possible is crucial.

Moisture is the enemy of dry ice and leaving it exposed to the air, especially in very humid conditions, will allow the dry ice to absorb moisture and this will soften the pellets and make them far less effective.

The supply of dry ice pellets is going to be crucial. You need to check out where you can source the pellets and they must be 3mm pellets. Large gas companies like SupaGas, BOC gases & Air liquide can generally supply dry ice but not all facilities can make 3mm pellets. Some of these companies will only produce 3mm pellets based on a minimum quantity and this can be as high as 200kg.

Price for pellets can vary massively, so don’t be put off by the first quote you receive. AKA Cleaning can generally negotiate reasonable rates for their customers with the suppliers. Their preferred supplier is SupaGas, however their outlets are very limited.

It is possible to manufacture your own pellets, but your usage needs to very high to make this viable.

4. The Operator

Training in the use of the blaster is also critical. Dry ice blasting is more of an art than a science. Results can vary greatly depending on the experience of the operator. Achieving the correct balance of air pressure, dry ice feed rate, length of hose and nozzle selection can make a huge difference to the efficiency and effectiveness of the clean. Getting the correct balance will also achieve the best economy of dry ice consumption and diesel fuel used to power the system.

Does your blaster vendor supply a detailed accredited training course for the equipment they sell?

So, it’s not as simple as some would have you believe. It is certainly a fantastic and magical cleaning system, but it is necessary to understand all the hurdles that need to be overcome to have an efficient, reliable, and easy to use system.

If you have any further questions or would like to discuss a dry ice blasting system for your application, contact AKA Cleaning.