- June 7, 2017

- No Comment

What’s it Like to Work in a Remote Mine in Africa?

Wherever you are in the world, mining is a demanding field of work to go into. Miners endure coal dust, excessive noise, vibration from operating certain machines, UV exposure (for open pit workers) and chemical hazards.

These are only a few of the risks associated with working out at the mines. The structure of a miner’s working schedule, the amount of time they spend away from family and the difficulty of maintaining a regular life can create a trying mix of emotions for their brains to bathe in. Life at the mines isn’t easy, especially in the face of the post-2011 downturn and resultant uncertainty in the industry.

However, this side of the work needs to be kept in perspective. Most miners are as happy to tell you about the benefits of where they work as the difficulties.

“I got more fear walking through a car park than I do a mine site, honestly. More fear riding a pushbike in Brisbane than if I went on the bottom of the pit with the excavators running flat-out, digging a hundred ton of copper out of the ground. Because on the site it’s controlled.”David Forth, Aussie crane operator working in Zambian copper mine

Mines these days have a huge focus on safety (with one Australian mine even trialing a robot from NASA to do all the work humans don’t want to). And, if you keep your eye out for international opportunities, a mining job can take you all over the world.

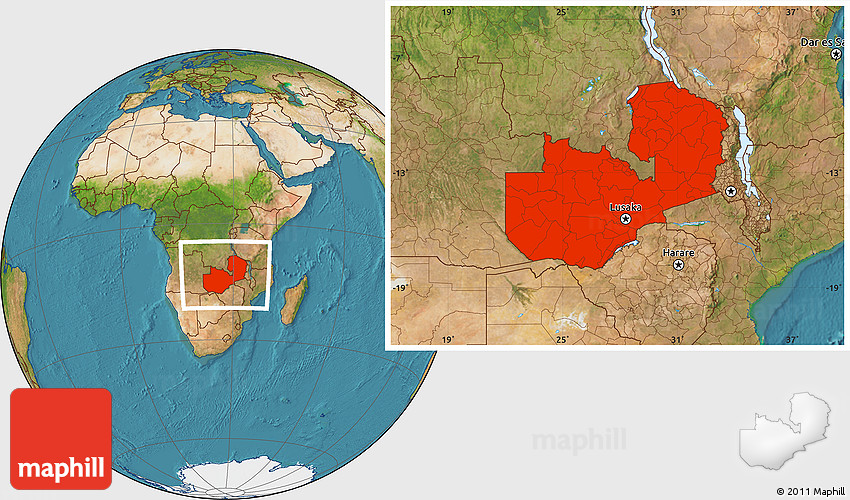

We spoke to Aussie crane operator and trainer, David Forth, who’s spent the last couple of years working in a copper mine in Zambia. In case it’s been a while since your last geography lesson, that’s here:

Knowing where Zambia is on the globe is all well and good but, zoomed out as far as we are here, you don’t get much of a feel for what’s actually going on down there. For a more tangible feel for the landscape of Zambia, here are some shots shared by Instagram users:

While the country David works in is already spectacular, the rotational nature of FIFO mining means workers get three weeks off at a time which they can use to go home or travel the world.

“Most of the expats fly home, some of them do a trip around the world, they’re three weeks off, they have the ability under your contract to you fly home, or you can, as long as the cost of the flight around the world is similar, if it’s the same. If it’s extra you pay extra.”

Mining in Africa: same-same but different

The mines all operate under very similar structured processes, regardless of their location. You still drill, blast, dig, put it on a truck, put it a through a crusher, through a process line, mill it, put it in a stockpile, put it on a train or another truck and ship it over to a refinery.

And, despite the African locale, there are no elephants, lions, zebras, giraffes or hippos to be found in the vicinity of the mine. According to David, the big differences are to be found in the little things, and the trips off site.

Mining in Africa: the machines

“We always gotta check the quality of the gear because we’ve had counterfeit equipment and parts delivered to site. People trying to make an extra few bucks out of it.”

Not such an issue when you purchase something online and the reality doesn’t quite match your expectations.

But when you’re dealing with massive machines and people’s lives, quality assurance is paramount. As a supervisor, trainer and operator, all of David’s roles benefit from making sure the right machines, parts and attachments are equipped in the mine.

The copper mine has a whole spectrum of cranes: small 13 tonne industrial ones, 30 and 80 tonne rough-terrain cranes, 275 tonne and 300 tonne crawler crane and a monster 450 tonne hydraulic all-terrain crane. (The biggest one in Africa before you get up to Nigeria and Egypt where the big oil and gas jobs are). There’s even a 20 tonne Australian Terex Franna, made in Brisbane.

The mine is flush with forklifts ranging from 3 to 12 tonne and David has an order in for 35 new ones. Then there’s the usual excavators, dump trucks, graders, dozers: your standard, large-scale mining machine fleet. While their biggest excavator doesn’t quite match up to the magnitude of the largest one in the world, they still dwarf the average excavator.

Mining in Africa: workers and safety

When it comes to labour, there is a substantial difference in pay and experience between Australia and Africa.

“Labour can be incredibly cheap. But it’s relative to the environment you’re operating in, production, and skills and everything too. Australian miners, you expect a lot more out of them. You don’t always get it, but you expect a lot more out of an Australian miner, being paid $100,000 over the year compared to a local man who might earn, honestly, $10,000 the whole year.”

As far as safety goes, David sees the concept that Africa would be more dangerous because it is less developed as a fallacy of logic. Having worked in both Australian and African mines, he estimates the accident rates are quite similar.

“They still have the same accidents, the same incidents, the same near-misses, as every other mine in the world. People say, ‘well that’s what happens when you get unpaid and unskilled workers,’ but no, it’s not. It’s human nature to stuff up from time to time.

Since I’ve been here there’s been two deaths. One dump truck fell off a wall, the other one burned to the ground with a guy inside. In the last month, we had two guys lose the tips of their fingers.”

While these accidents sound extreme, David says its par for the course in dangerous work sites anywhere around the world. They’re not Africa-specific but humanity-specific.

“It’s a human mindset. People take the easiest route to get shit done. It’s the truth. They do it here, in Australia. They do it everywhere.”

All in all, the aim of the mining company is to help educate the local workforce so they can run the mine themselves. There are strict rules on how many expats and foreign workers can be employed on site, even extending to the length of their contracts. David will be leaving the mine soon, having passed his knowledge and experience on to those Zambian workers selected to take over supervision once he leaves.

Culture shock (or not)

As far as the amenities of the mine site go, there’s little difference between the copper mine David works at in Africa and a mine in Australia.

“We got beer, we got pay TV, we got a bar, a takeout joint, internet, everything. But no word of a lie, you can go not even a kilometer from the gate of the mine, to people who are living in mud huts with no running water, no perma-sewage. But they all have smartphones.”

There’s western influence everywhere. Even those who live without electricity have smartphones and enough access to western culture—via snatches of access to internet—to know they want money, fame and fast cars. But they don’t have running water, sewage or electricity to their house. To give power to their modern devices, workers get battery banks, charge them up at the mine, and take them home so their household can get a few charges out of it.