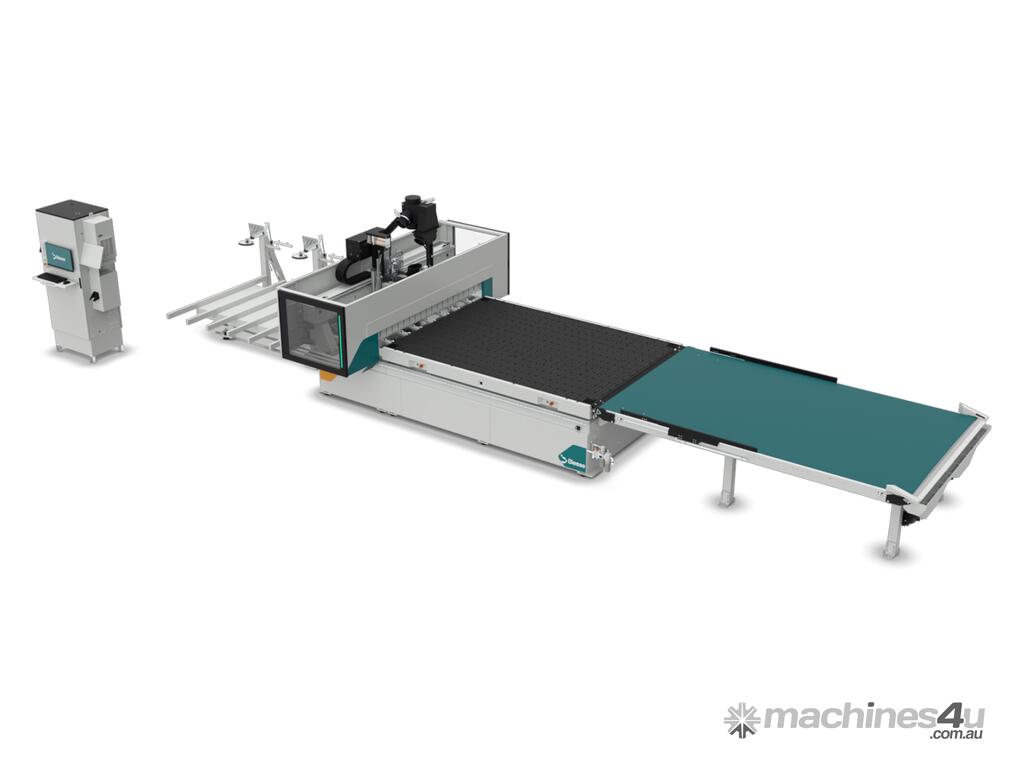

Biesse Rover Multi Go N G Machining centre for milling, boring and nesting operations on panels

Easy and compact machining for high quality nesting production

Outstanding results within a compact footprint, seamlessly integrated into workshops with limited space.

Elevate your manual manufacturing with automation, quality, repeatability and productivity.

Simplify your workflow

From CAD-CAM software straight to finished part.

Check your programs with the 3D simulation. Avoid mistakes and predict production time, keeping costs under control.

A complete job

Cabinet frames, stretchers, drawers, doors: all furniture processing in a single machine, with absolute precision.

Elevate product quality

Unmatched repeatability and high precision on finished parts.

No more late touch-ups discovered during assembly and installation.

Autonomy

Loading and unloading devices significantly reduce effort and processing time.

So you can focus on other tasks while the machine does the job.

No material waste

B_NEST nesting optimizer maximizes material usage, reducing waste and offcuts.

Quick tools and aggregates setup

Tool magazines for tools and aggregates, no operator intervention for tool change and adjustments.

Designed to fit

Full accessibility to safely reach all sides of the machine without obstructions and no ground obstacles.

Nesting of cabinet and kitchen doors

Cut, rout and drill panels with precision tools

Stack machining

Secure handling of stacked, breathable and non-flat panels using pressure rollers.

Process completion using pods or clamps

Vacuum pods to work on side faces.

Ideal for secondary processing, reworking and solid wood machining.

Please contact us for more information.