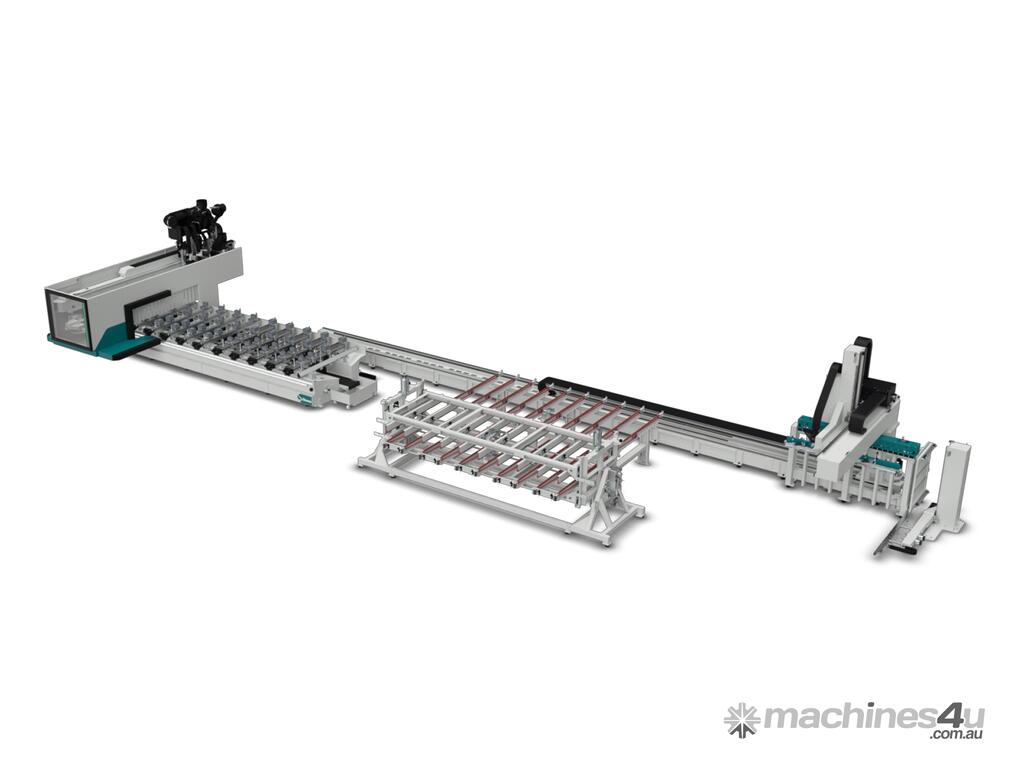

Biesse Stream Multi Pro MG-BP Machining centre for milling & boring operations on panels, solid wood

A futureproof workflow for your company

Technology meets quality to automate production. A multimachining center with autonomous loading and unloading for best performance.

Loading, overturning and unloading

We have introduced the panel overturner to enable operations on the bottom face, streamlining the entire machining process while minimizing operator effort and presence.

Automation improves panel handling

The whole automated process reduces damage and mistakes that can occur with manual handling of panels or doors.

Be always sure about the panel being processed with a system of photocells (QR code reader on both top and lateral side) on board of the handling device.

Panel loading and unloading without human effort

The operator just loads and unloads the stack out of the machine bay, without handling heavy and big panels anymore: a big safety improvement.

Optimized machining cycle boosts productivity and reduces time

An optimized working cycle reduces machining time and increases productivity.

Thanks to operating units and Toologic tool optimizer, the Stream Multi Pro MG-BP performs tasks in hidden time, with optimal toolchanger setup.

Increase your productivity up to +32%

Rover Multi Pro M G can be equipped with a double Y axis: 2 operating units (one 5 axis group and one 4 axis vertical electro-spindle) working combined to reach a production peak.

4... 3... 2... 1... table positioning done

Automatic working table positioning in just 4 seconds

B_SOLID CAD-CAM

This software allows to create any program, which is then translated into precise instructions for the CNC: minimize human errors and perform accurate machining of parts.

Doors

Skilled in managing all components of internal doors.

Panel furniture

Capable of efficiently managing the loading and unloading of panels for furniture applications, with particular care for delicate finishes.

Please contact us for more information.