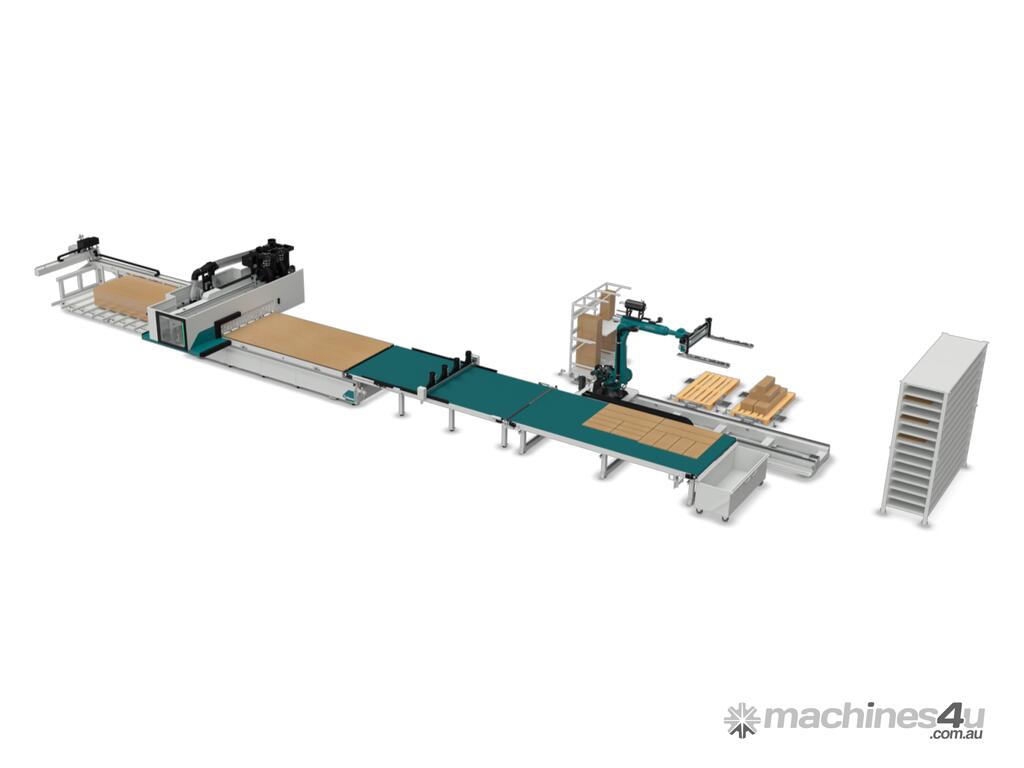

Biesse Stream Multi Pro NG SR Machining centre for milling, boring and nesting operations on panels

Boost your production with seamless automation

When high dynamics work center meets the integration requirements and production needs.

One partner for seamless integration.

To manage the entire machining process from automated loading to robotic unloading*.

Optimized Solution for Streamlined Production and Workflow

Solution for customers with a fairly standardized production process for materials and finishes, working with medium to large orders and an organized workflow, requiring well-organized stacks, traceability, and error-free operations. The operator is only engaged during the brief stages of stack loading and outbound pallet sorting.

Production Boost

High-Dynamics Machine Version Solution. This solution will enable increased production while maintaining high-quality standards.

Zero mistakes

Automated panel handling from pallet to workpiece eliminates operator intervention, with sorting by job, customer and size. Ensures zero rework from damaged or lost parts.

3D-Vision system

A 3D-vision system integrated in the robot allows to scan panel position.

Labels are not required.

Operator Role: From Physical Tasks to Supervisory Responsibilities

The operator will act as a line supervisor, no longer accountable for loading or unloading the machine, reducing physical effort and enabling higher-value tasks.

Integration of processes

Optimized workflow ensures seamless integration of processes, minimizes downtime, enhances productivity, and maximizes overall efficiency

Panel applications

Capable of efficiently managing the loading and unloading of panels for furniture applications, with particular care for delicate finishes.

Please contact us for more information.