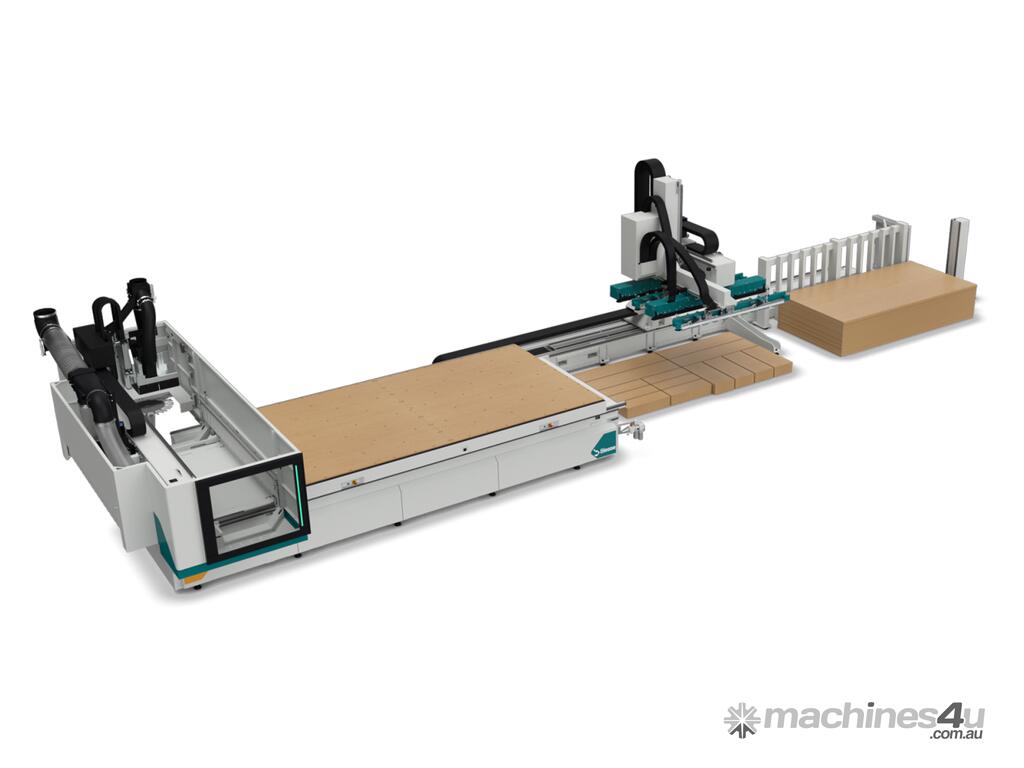

Biesse Stream Multi Up NG-BP Machining centre for milling, boring and nesting operations on panels.

Autonomous machining center for panels application, ensuring optimized time cycle

Less effort for the operator during the process, resulting in more productivity of the nesting cell.

Perfect fit for companies seeking for autonomy in process and optimized manpower.

Efficient process without scratches

Thanks to the automatic loading/unloading via vacuum or sponge modules, panel will be handled without being dragged along all the machining process.

No scratching on surface for a better result.

Automation improves panel handling

The whole automated process reduces damage and mistakes that can occur with manual handling of panels.

Be always sure about the panel being processed with a system of photocells (QR code reader on both top and lateral side) on board of the handling device.

Firm grip on critical pieces

Handling device can be equipped with Multizone system to guarantee a stable grip in any condition.

VACUUM PODS can be upgraded with

High flow for rough surfaces

High flow together with compressed air for porous materials

SPONGE MODULES can be upgraded with

High flow for delicates or panels with emptying/grooves

Effortless loading and unloading

Multi-machining working cell is optimized to improve operator's safety, raise productivity and reduce downtimes.

Multiple configurations available depending on customer's need.

Optimized tools management for a better autonomy

There will be no more downtime for retooling the tool magazines.

16 positions revolver on X axis is always included.

Up to -25% on daily consumption

Dynamic vacuum system and green function will let the machine optimize energy usage.

Optimized management of vacuum flow and air consumption to ensure savings during processing.

B_SOLID CAD-CAM and B_NEST software

B_SOLID is available from design to nesting optimization, with all the features and additional modules available for additional scope.

Panel furniture

Capable of efficiently managing the loading and unloading of panels for furniture applications, with particular care for delicate finishes. The shaped parts or nesting element could be automatically download only if compatible with the gripping device of the unloading system. If the elements processed, for size or number, cannot be discharged atomically, a manual procedure must be used.

Please contact us for more information