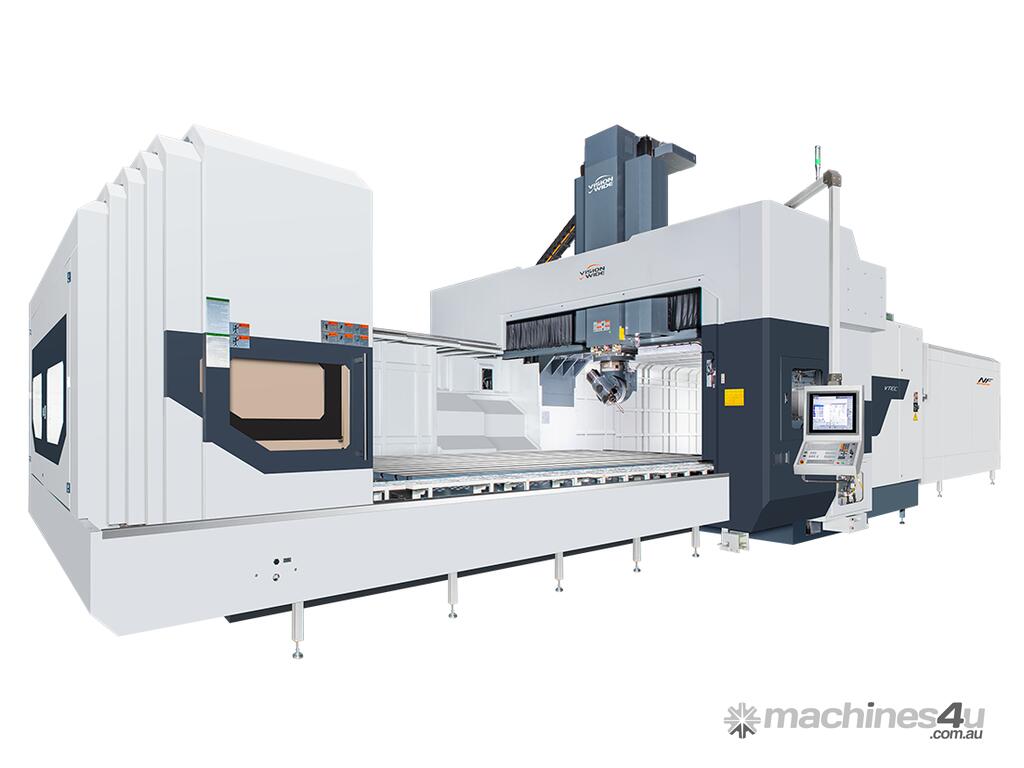

The Vision Wide NF Series is a heavy-duty 5-face machining centre built for large, complex components requiring accuracy, rigidity and reliable long-term performance.

Designed around a double-column structure, the NF Series delivers high material removal rates while maintaining excellent geometric accuracy across long travels.

This platform is well suited to general engineering, die and mould, energy, transport, aerospace and large structural machining applications.

Key Features:

- 5-face machining capability with automatic attachment head change

- Double-column design for outstanding rigidity and thermal stability

- Heavy Meehanite cast iron construction with stress-relieved structure

- High-torque spindle options for both heavy cutting and fine finishing

- Automatic vertical / horizontal tool change

- TCPM intelligent control for multi-angle machining accuracy

- Designed for continuous, high-load production environments

Machine Configuration Highlights:

- X-axis travel options from approx. 3,100 mm to 10,100 mm

- Multiple Y- and Z-axis travel configurations available

- Choice of box way or linear way ram designs depending on application

- Gear-type, direct-drive or built-in spindle options

- Enclosed guarding available (standard or optional roof)

Typical Applications:

- Large die and mould machining

- Structural steel and alloy components

- Aerospace aluminium machining

- Automotive tooling and engine components

- Energy, rail and heavy industrial parts

Why Choose the Vision Wide NF Series:

This machine is engineered for workshops that need consistent accuracy on large workpieces, without sacrificing cutting power or uptime. It bridges the gap between ultra-heavy portal machines and high-speed machining centres, offering flexibility, strength and long-term reliability.